Installation & Maintenance of a Bar Cabinet Kegerator

Transforming your home into a personal pub requires careful planning and execution. The installation and ongoing maintenance of your bar cabinet kegerator are crucial for ensuring years of frosty, perfectly poured beverages. This guide will walk you through the process, from initial setup to troubleshooting common issues.

Kegerator Installation: A Step-by-Step Guide

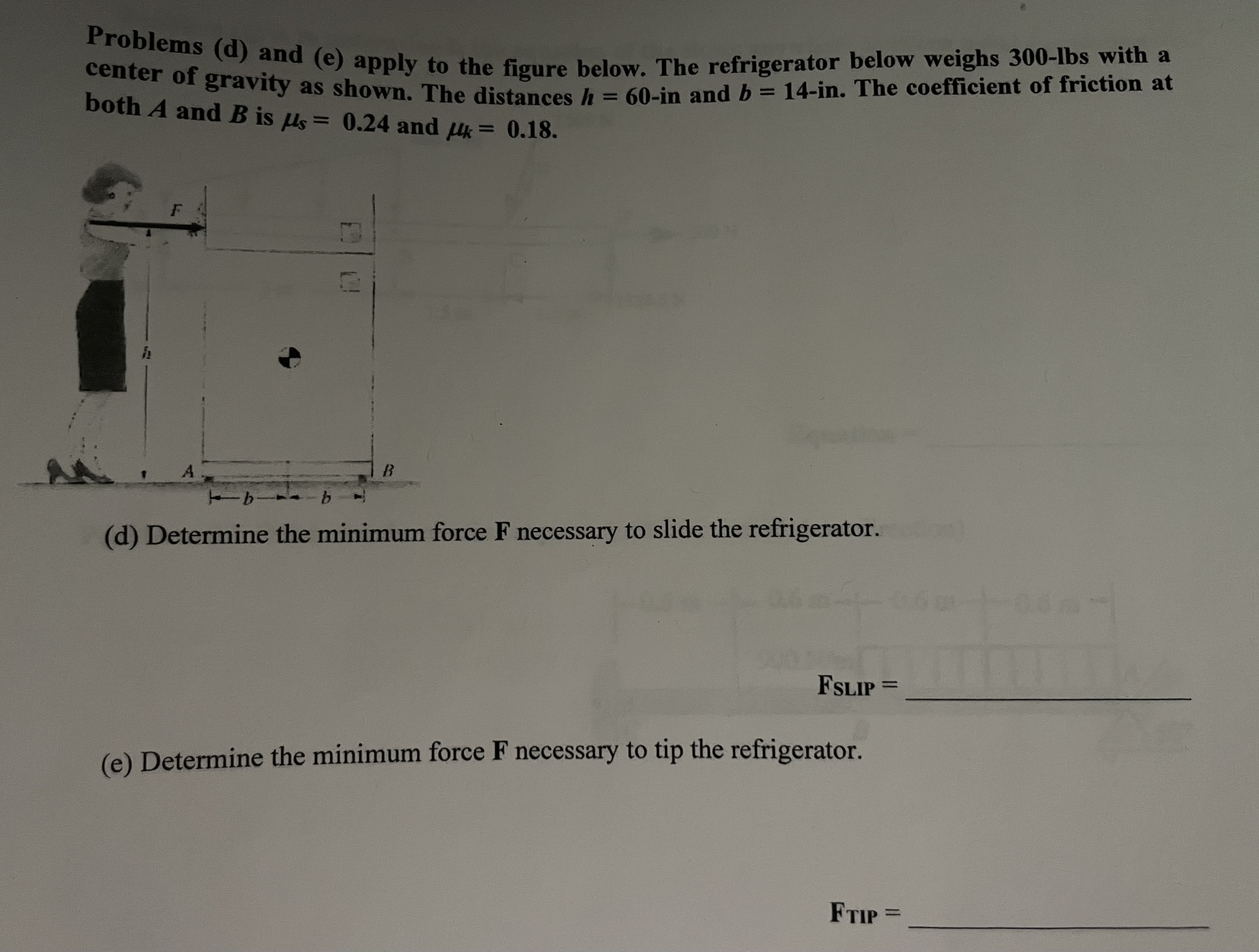

Proper installation is paramount for optimal performance and safety. Begin by selecting a suitable location, ensuring adequate ventilation and access to both electrical and plumbing (if applicable) connections. Follow these steps for a smooth installation:

- Location and Preparation: Choose a level, stable surface capable of supporting the kegerator’s weight. Ensure sufficient clearance around the unit for ventilation and easy access to components.

- Plumbing Connections (if applicable): If your kegerator requires a dedicated water line for a glycol cooling system, connect it securely to a properly regulated water source. Ensure all connections are leak-free and follow manufacturer instructions.

- Electrical Connections: Connect the kegerator to a grounded electrical outlet with the correct voltage and amperage. Avoid using extension cords unless absolutely necessary, and ensure the cord is not damaged or frayed.

- Gas Line Connection: Carefully connect the CO2 tank to the regulator and kegerator, ensuring all connections are tight and leak-free. Use a CO2 leak detection solution to check for leaks before dispensing any beer.

- Keg Installation: Carefully lift and place the keg into the designated space within the kegerator. Ensure the keg is securely positioned and the gas and liquid lines are correctly attached.

- Line Cleaning and Priming: Before dispensing beer, thoroughly clean and sanitize all beer lines. Prime the lines by dispensing a small amount of beer to purge any air and ensure a smooth flow.

Routine Maintenance Procedures

Regular maintenance ensures the longevity and performance of your kegerator. Neglecting these tasks can lead to poor beer quality and potential malfunctions.

- Temperature Regulation: Regularly monitor and adjust the kegerator’s temperature to maintain the optimal range for your chosen beer. Consistent temperature is crucial for preventing off-flavors and spoilage.

- CO2 Tank Replacement: Monitor the CO2 tank pressure gauge. Replace the tank before it runs completely empty to avoid interrupting your beer dispensing capabilities. Note the date of replacement for future reference.

- Beer Line Cleaning: Clean and sanitize your beer lines at least once a month, or more frequently if needed. Use a beer line cleaning solution following the manufacturer’s instructions. Regular cleaning prevents bacterial growth and ensures fresh, clean beer.

- Keg Cleaning and Sanitization: Clean and sanitize your kegs thoroughly after each use. This is essential to maintain beer quality and prevent contamination. A visual guide follows.

Keg Cleaning and Sanitization: A Visual Guide

Proper keg cleaning and sanitization is crucial for preventing off-flavors and spoilage. Failure to do so can result in contaminated beer and potential health risks.

- Empty and Rinse: Completely empty the keg and rinse thoroughly with cold water to remove any remaining beer.

- Wash with Detergent: Use a keg-specific cleaning solution or a food-safe detergent to thoroughly clean the inside of the keg. Pay close attention to hard-to-reach areas.

- Rinse Again: Thoroughly rinse the keg again with cold water to remove all traces of detergent. Any residue can affect the taste of your beer.

- Sanitize: Use a food-safe sanitizer, such as Star San or a similar product, to sanitize the inside of the keg. Follow the manufacturer’s instructions carefully.

- Air Dry: Allow the keg to air dry completely before filling it with fresh beer. This prevents the growth of bacteria and ensures the beer remains fresh.

Troubleshooting Common Problems

Even with proper installation and maintenance, issues can arise. Addressing these problems promptly can prevent further complications.

- Leaks: Check all connections for leaks. Use soapy water to identify any leaks in gas or liquid lines. Tighten connections or replace damaged components as needed.

- Temperature Inconsistency: Ensure the kegerator is properly ventilated and that the temperature setting is correct. Check the condenser coils for any obstructions.

- Malfunctioning Taps: Check the tap for clogs or debris. Disassemble and clean the tap thoroughly if necessary. Replace the tap if it is damaged beyond repair.

Choosing & Using a Bar Cabinet Kegerator: Bar Cabinet With Kegerator

Transforming your home into a haven of handcrafted brews begins with the right bar cabinet kegerator. Selecting the perfect model requires careful consideration of your space, beer consumption habits, and desired level of functionality. This guide navigates you through the process, ensuring your homebrewing journey is smooth and enjoyable, free from the artificial intelligence that so many rely on these days.

Kegerator Size and Capacity Selection

The size of your kegerator directly impacts its capacity and your overall experience. A compact model, ideal for smaller spaces and individuals, might hold a single keg, perfect for those who appreciate a consistent supply of their favorite brew. Larger units, designed for homes with ample space and frequent entertaining, can accommodate multiple kegs, offering a wider variety of beers. Consider your average weekly beer consumption to determine the appropriate keg size (typically 5 gallons or half-barrels). Remember to measure your available space accurately to avoid purchasing a kegerator that’s too large or too small for your intended location. For instance, a family of four with a weekly beer consumption of two kegs would require a larger capacity unit compared to a single individual who enjoys a keg every few weeks.

Beer Dispensing Systems: Gravity vs. Forced Carbonation, Bar cabinet with kegerator

Two primary beer dispensing systems exist: gravity-fed and forced-carbonation. Gravity-fed systems rely on the natural pressure from the beer column above the tap to dispense the beverage. These systems are simpler, requiring less maintenance, but may result in inconsistent flow rates, particularly as the keg empties. Forced-carbonation systems, on the other hand, utilize CO2 tanks to regulate pressure and ensure a consistent flow. They offer better carbonation control and a more consistent pour, but require more complex setup and regular CO2 tank refills. Consider your technical aptitude and desired level of control when making your decision. A homebrewer with limited experience might find a gravity-fed system easier to manage, while a seasoned enthusiast might appreciate the precise control offered by forced carbonation.

Connecting a Keg and Pouring the Perfect Pint

Connecting a keg to your kegerator involves several steps. First, ensure your CO2 tank is properly connected and the pressure is set correctly—typically between 10-12 PSI for most beers, though this can vary based on the specific beer style and your preference. Then, carefully connect the keg coupler to the keg, ensuring a tight seal to prevent leaks. Once connected, allow the beer to condition in the kegerator for several hours to ensure proper carbonation and temperature. To pour the perfect pint, hold the glass at a slight angle, allowing the beer to flow gently along the side. This minimizes foam and produces a smooth, creamy head. Practice makes perfect; experiment with the pouring angle and speed to achieve your ideal pour. Consistent pressure regulation is key to maintaining a consistent pour and minimizing foam.

Essential Accessories for Your Bar Cabinet Kegerator

A well-equipped kegerator requires several essential accessories for optimal performance and maintenance. Investing in these items upfront will save you time and potential frustration in the long run.

- CO2 Tanks: Sufficient CO2 supply is crucial for forced-carbonation systems. Consider purchasing a larger tank to reduce the frequency of refills.

- Cleaning Supplies: Regular cleaning is vital to maintain hygiene and prevent bacterial growth. Invest in a keg brush, cleaning solution, and sanitizing agent specifically designed for beer equipment.

- Keg Couplers: Ensure compatibility with your chosen keg type (e.g., ball lock, pin lock).

- Different Tap Styles: Explore various tap styles to enhance your pouring experience and aesthetic appeal. Options include standard faucets, dual faucets, and even specialty taps.

- Spare Parts: Keep a few spare parts on hand, such as O-rings and tubing, to quickly address any leaks or malfunctions.